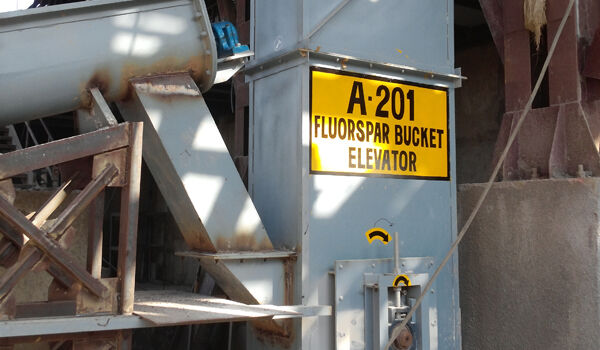

Bucket Elevator

A bucket elevator can elevate a variety of bulk materials from light to heavy and from fine to large lumps.

A centrifugal discharge elevator may be vertical or inclined. Vertical elevators depend entirely on the action of centrifugal force to get the material into the discharge chute and must be run at speeds relatively high. Inclined elevators with buckets spaced apart or set close together may have the discharge chute set partly under the head pulley. Since they don’t depend entirely on the centrifugal force to put the material into the chute, the speed may be relatively lower.

Nearly all centrifugal discharge elevators have spaced buckets with rounded bottoms. They pick up their load from a boot, a pit, or a pile of material at the foot pulley.

The buckets can be also triangular in cross section and set close to on the belt with little or no clearance between them. This is a continuous bucket elevator. Its main use is to carry difficult materials at slow speed.

Early bucket elevators used a flat chain with small, steel buckets attached every few inches. While some elevators still are manufactured with a chain and steel buckets, most current bucket elevator construction uses a rubber belt with plastic buckets. Pulleys several feet in diameter are used at the top and bottom. The top pulley is driven by an electric motor.

The bucket elevator is the enabling technology that permitted the construction of grain elevators. A diverter at the top of the elevator allows the grain to be sent to the chosen bin.

A similar device with flat steps is occasionally used as an elevator for humans, e.g., for employees in parking garages. (This sort of elevator is generally considered too dangerous to allow use by the public.)

BUCKET ELEVATOR TYPES

There are three common bucket elevator designs seen in bulk material handling facilities worldwide:

- 1. Centrifugal Discharge Elevator – Typically, this is the style of elevator used in grain handling facilities we are all familiar with along rivers, ports or on the farm. The elevator buckets discharge product freely by the use of centrifugal force. Product flings out of the bucket into the discharge spout located at the top of the elevator.

- 2. Continuous Discharge Elevator – This style bucket elevator is used typically to discharge sluggish and non free flowing product where the elevator buckets discharge on top of each other. Speeds are run in the 125 fpm range to accomplish this type of centrifugal force.

- 3. Positive Discharge Elevator – Elevator design where the buckets are used to elevate commodities such as popcorn, candy and potato chips where the utmost concern is on gentle handling and finished food grade applications. This style elevator bucket operates off a double strand chain where they are held in place by two pins so the bucket is allowed to freely swivel. To discharge the bucket it’s mechanically tripped to flip and discharge but until this action the bucket is held parallel with the floor and upright. These elevators typically form an “S” or “L” in design and run throughout a plant.